EVAplus

Optical methods for material identification and qualification

Project Duration

03/2022 – 02/2025

Project Lead

Prof. Dr. Ralph Gottschalg

Project Management

Sebastian Dittmann

Funding

BMWK | 03EE1112E

Project Motivation

The long-term stability of photovoltaic (PV) modules is of outstanding importance for the energy production costs of PV. Manufacturers of PV modules give a 25-year performance guarantee on 80% of the output power. This extreme stability can only be achieved if the encapsulation is perfectly processed, as this ensures protection against environmental influences. This doesn’t always work. There are various reports that up to 30% of all modules in the field show abnormalities. These abnormalities are not necessarily problematic and cannot always be attributed to the encapsulation. It can also just be a matter of visual effects, such as a slight discoloration of the encapsulation that is not relevant to operation, or serious problems in the back sheet.

However, anomalies often lead to very costly investigations or reduce the value of an asset based on the assumption that the operational risk is higher due to an anomaly. The proportion of encapsulation-related abnormalities is difficult to quantify, but a conservative estimate would be an amount of 20%.

The ambition of EVAplus is the development of an encapsulation quality control, which achieves a reduction of encapsulation anomalies in the field by 20% and an increase in the production yield of a module manufacturer by 2% (increase in speed through optimized lamination and reduction of rejects by 10%).

Overall goals

Definition of the ideal degree of cross-linking for module reliability from investigations of field returns and climatic chamber tests and weathering on specially manufactured test specimens

Development of a non-destructive measurement technology for determining the degree of cross-linking and other polymer film parameters

Developing an Industry 4.0 approach to field-reliable lamination. This requires result-controlled lamination instead of the time and temperature-controlled process currently used

Quality assurance of the EVA qualities actually arriving on the field to identify any production problems.

Sub-Project Goals

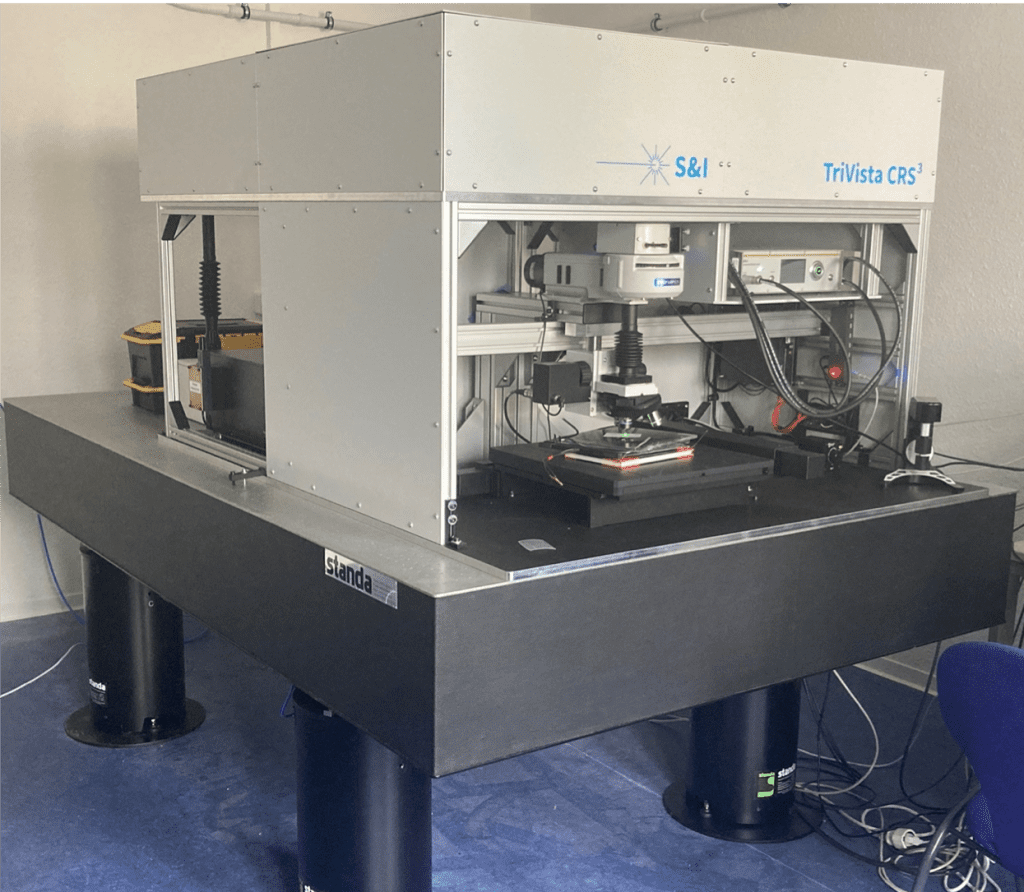

The HSA sub-project will develop optical measurement methods that will enable rapid indication of variations. Optical material detection and characterization of encapsulation foils.

Development of a statistical risk model

Creating optical fingerprints of foil materials

Material aging modelling

Development of digital twin measurement process

sensitivity analysis for material condition parameters

development of optical methods for

Detection of microstructural and process-relevant material parameters

Our Partners

The partners with whom we collaborate on this project