Influence of the material combination on the UV fluorescence of films for photovoltaic modules

Zonghan Jiang1, Patrick Wessel1,2, Sebastian Dittmann1,2, Carlos Meza 1, Ralph Gottschalg 1,2

1 Hochschule Anhalt University of Applied Sciences, 06366 Köthen (Anhalt)

2 Fraunhofer-Center für Silizium-Photovoltaik CSP, Halle (Saale)

Motivation and Goal

Demonstration of a method to characterize the changes in fluorescence produced by different combinations of materials during the aging process;

- Trend and change in fluorescence with the same encapsulation material over the aging period;

- Trend and change of fluorescence in different encapsulation material over the aging period and their respective properties;

- Exploring the data contained in the different color layers of UVF images.

Experimental Process

The proposed nondestructive method for studying the aging of different material combinations can be divided into the following steps:

1 – development and optimization of a UVF gauge prototype.

2 – different encapsulation materials are aged in 2 climatic chambers (DH und DH-UV) at different time (e.g., 0h, 250h, 500h…):

3 – regular measurements with the UVF meter during the aging process.

4 – calculation of the average pixel value of a polymer fluorescence image.

5 – analysis and comparison of differences between color layers of RGB images to improve the evaluation quality.

6 – comparison of the change of fluorescence in UVF images with the same encapsulation material during aging.

7 – comparison of UVF images of different encapsulation material combination at the same aging stage.

Design of the UVF measuring device (prototype)

Components of the UVF prototype

- 365nm UV LED

- Aluminum frame

- Aluminum ceilings

- Heat sink

- Power supply

- Camera

(prototype)

Polymers for encapsulation :

1.ENC1 (Film material: BPO),

2.ENC2 (Film material : EVA),

3.ENC4 (Film material : POE)

1.BS1 (Basic material: PPE)

2.BS4 (Basic material: FFC//PET//FFC)

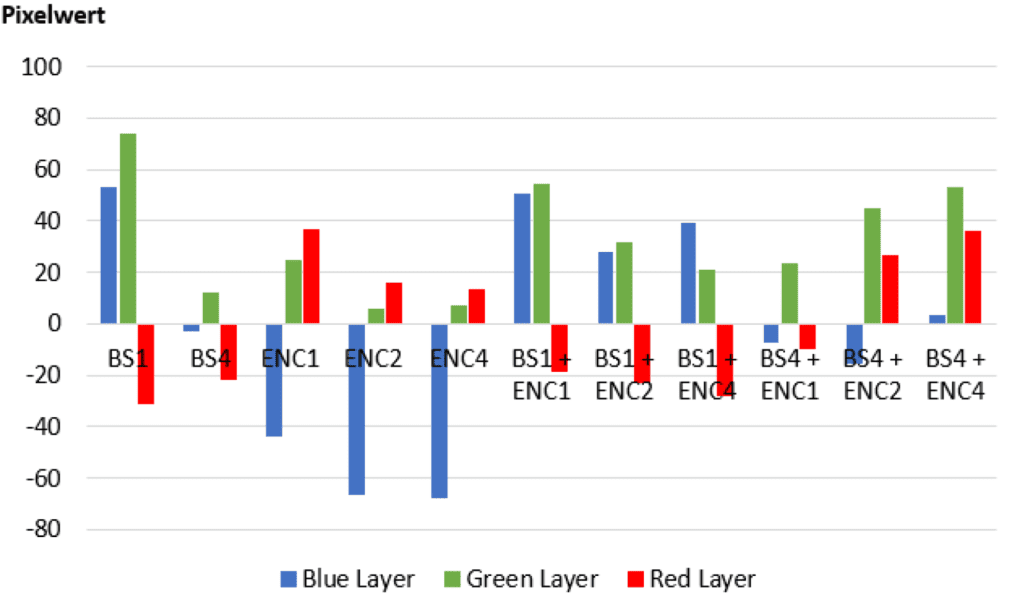

Results

(With DH-UV Aging Condition)

(With DH-UV Aging Condition)

Summary and next steps

– A workflow for quantitative field analysis of encapsulations and a method for nondestructive evaluation of material condition for module aging was presented.

– Different films and their combinations exhibit different fluorescence changes during their aging process.

– The changes in pixel values in the RGB layers of UVF images show greater diversity than in the gray image.

– Optimization of the test (e. g. the homogeneity of the UV light, algorithm for calculation).

– Aging of the samples will continue and further data and analysis will be provided later.